Trinitas is developed by Linköping University for mainly research. It provides many forms of Finite Element Analysis and is quite useful. As far as we are aware its commercial usage price is very low. We tried the 30 day limited version and our impression is as follows.

It has an integrated CAD suite, despite rather primitive, sufficient for many topology optimization needs. It has a pre-processing section which again is primitive however sufficient. Its meshing capabilities are sufficient with respect to its price. It has 2D structured and un-structured meshing capabilities and 3D structured meshing capabilities. Defining loads, contact conditions and other boundary conditions is easy. However the software crashes when, for instance prescribed displacements are used in topology optimization. It is possible to exclude volumes, however this seems to slow down the optimization process significantly. We used various models to test the topology optimization process and it is satisfactory.

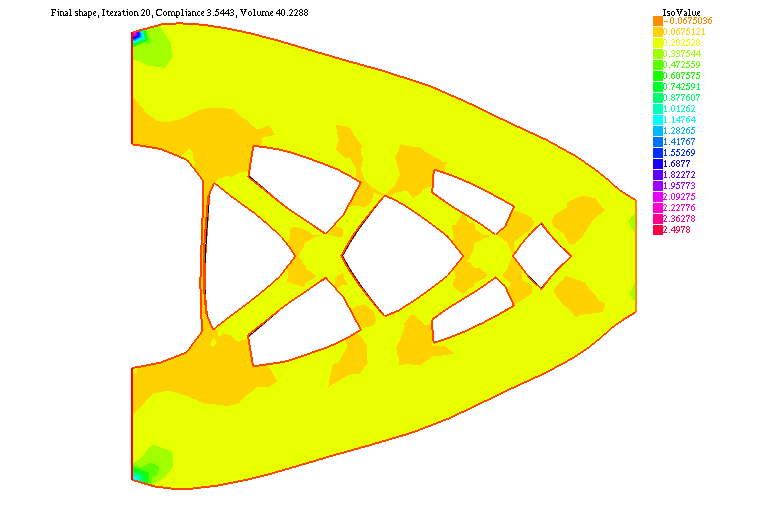

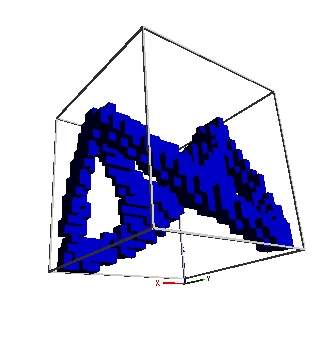

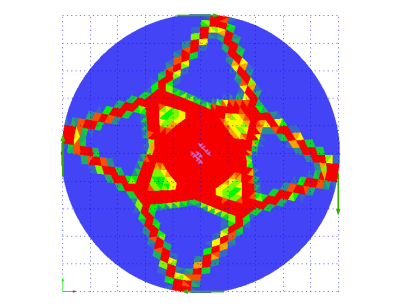

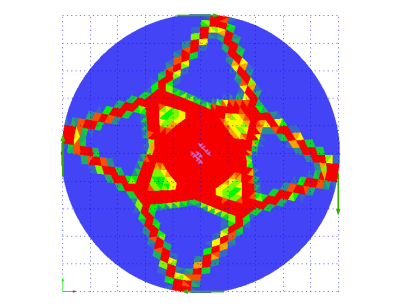

The result of a 2D optimization at rather low resolution gave a very neat result

One drawback is that the software cannot use more than one core of CPU, this slows down the process tremendously. Also when using too many elements Trinitas crashes. It also cannot import models from common formats, so we have to rely on its own capabilities. It does not have advanced features like die draw direction to account for manufacturing methods to be used.

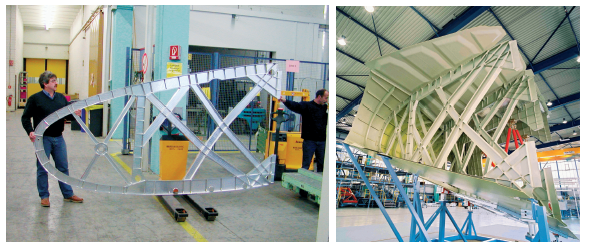

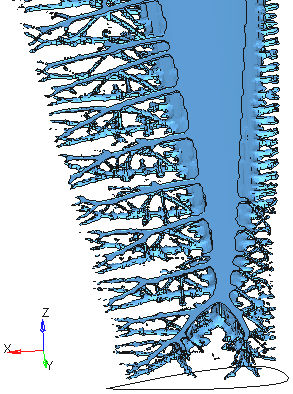

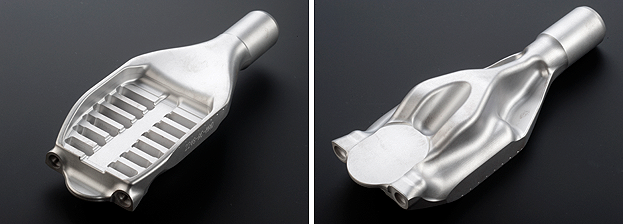

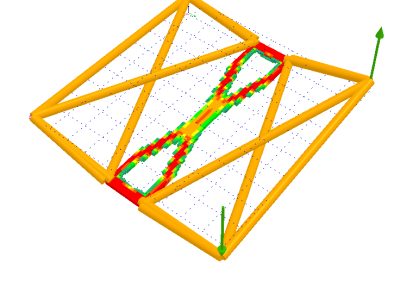

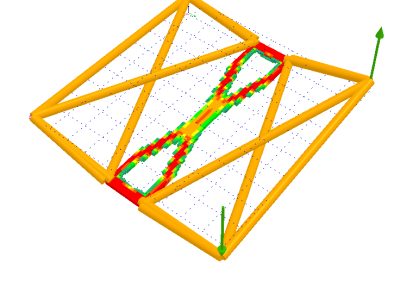

A 3D application

Despite many drawbacks Trinitas does not have any rivals at its price point. If you cannot afford high-end software, Trinitas is the way to go. At their homepage you can see it has many useful features, including Shape optimization, that is used very closely with topology optimization or Transient Heat Transfer analysis.