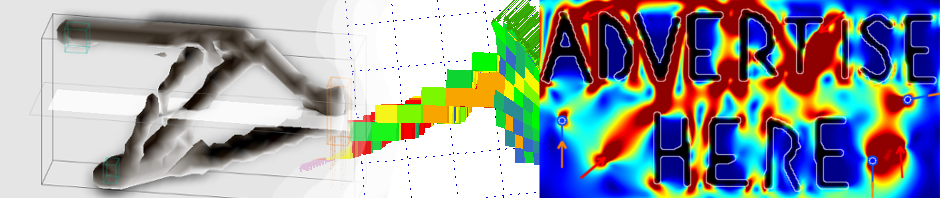

Weight reduction of a compact car’s front section was studied in this article (link). Using topology optimization, and interpreting the results in two different ways, one cost effective and one weight optimized structure is developed. Cost effective structure uses mostly steel and some Al extrusions. Weight optimized one uses lots of aluminium, steel where necessary and magnesium for strut towers. Wheelhouses in both concepts are made of plastic. Respectively %18 and %38 weight reductions are reported. Also %7 and %31 cost increase is observed.

Tags

2D 3-D print 3D Additive Layer Manufacturing aerospace Aesthetics Airbus aircraft ALM alternative AMG architecture article Audi automotive bayer bearing beginner bell crank billet biomimic. dendrite BLOODHOUND BMW Body in white bolt Bracket brake Brembo bridge caliper Car casting CFRP frame free hybrid interpretation machining magnesium mesh Optimization race software Topology wing-

Recent Posts