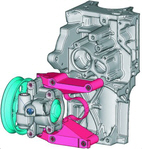

I this study dating 2004 (link) Ford used structural optimization to replace a polyamide bracket with an aluminum one. The polyamide bracket was getting more expensive due to the original manufacturers collapse. The analysis yielded a lighter, more rigid and cheaper aluminum bracket, with higher natural frequency. The project saves 1.1 M USD in the first year.

Tags

2D 3-D print 3D Additive Layer Manufacturing aerospace Aesthetics Airbus aircraft ALM alternative AMG architecture article Audi automotive bayer bearing beginner bell crank billet biomimic. dendrite BLOODHOUND BMW Body in white bolt Bracket brake Brembo bridge caliper Car casting CFRP frame free hybrid interpretation machining magnesium mesh Optimization race software Topology wing-

Recent Posts