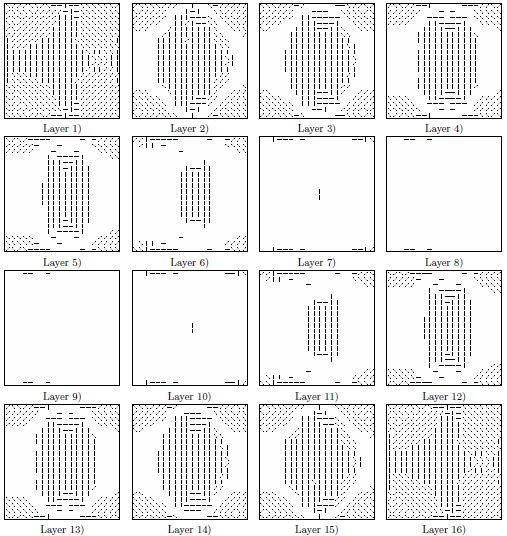

This article (link) titled “Buckling Optimization of Laminated Hybrid Composite Shell

Structures Using Discrete Material Optimization” studies optimization of wind turbine blades using Discrete Material Optimization (DMO). First a simply supported plane is optimized using continuous fibers and foam. A distribution of laminate areas with foam and continuous fibers with certain orientations is obtained. A very nice distribution is observed. Then a wind turbine blade is optimized using CFRP, GFRP and foam materials. It is stated that due to errors in the used shell model the results were not reliable, thus the results were not investigated much.

Tags

2D 3-D print 3D Additive Layer Manufacturing aerospace Aesthetics Airbus aircraft ALM alternative AMG architecture article Audi automotive bayer bearing beginner bell crank billet biomimic. dendrite BLOODHOUND BMW Body in white bolt Bracket brake Brembo bridge caliper Car casting CFRP frame free hybrid interpretation machining magnesium mesh Optimization race software Topology wing-

Recent Posts