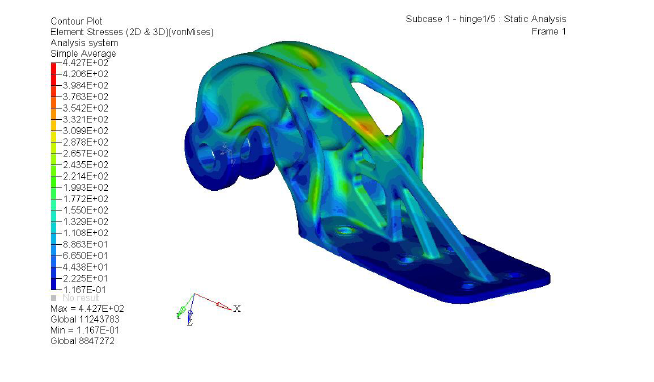

EADS Innovation Works optimized Airbus A320 nacelle hinge bracket (link). The manufacturing method of choice was Additive Layer Manufacturing (ALM), so no manufacturing constraints was necessary. The component was originally made of steel , but now the material of choice was Ti6Al4V. A %64 reduction in weight was obtained, with a preserved level of stiffness and decreased (halved) maximum stress, and a bit lowered maximum bolt force. The optimization was done in two stages, the first on was scraped, where the errors seems to be origination from improper boundary conditions. The final structure seems not to be utilising the full potential of free ALM structures.

Tags

2D 3-D print 3D Additive Layer Manufacturing aerospace Aesthetics Airbus aircraft ALM alternative AMG architecture article Audi automotive bayer bearing beginner bell crank billet biomimic. dendrite BLOODHOUND BMW Body in white bolt Bracket brake Brembo bridge caliper Car casting CFRP frame free hybrid interpretation machining magnesium mesh Optimization race software Topology wing-

Recent Posts