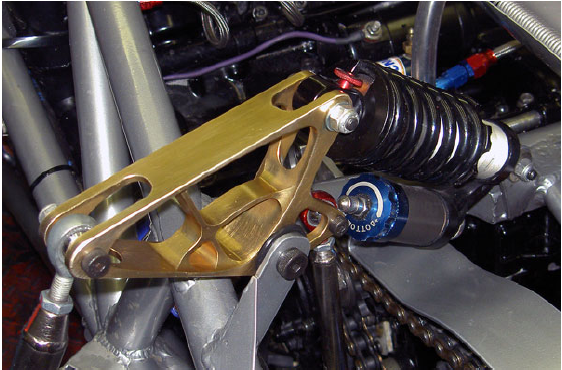

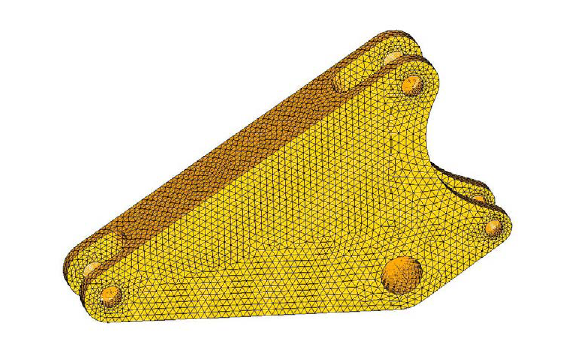

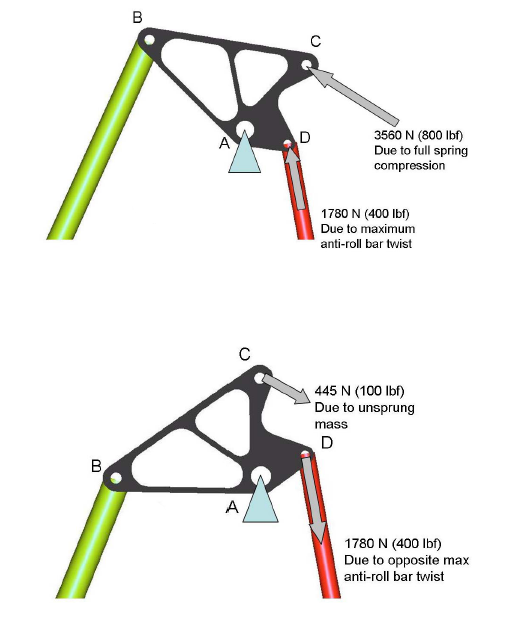

As a master thesis study (link) a Formula SAE cars bell crank was topology optimized. The bell crank is highly stressed, the largest load acting on it being 3500 N. The cranks weight was reduced to 140 grams which is a 24% weight loss also the load required to plastic deform the component was increased to 15.9 kN which is 30% more that previous design. The optimized shape looks a lot like the classical cantilever optimized shape. The optimum shape was obtained with a draw direction constraint.

The bell-crank was milled from 7075-T6 aluminum alloy.